-

Applications

Drones/Power Plants

-

Applications

Elevators/Escalators

-

Applications

Electronic Vehicles

-

Applications

Aircrafts, Ships

-

Applications

Factory Machines, Robots

SDG

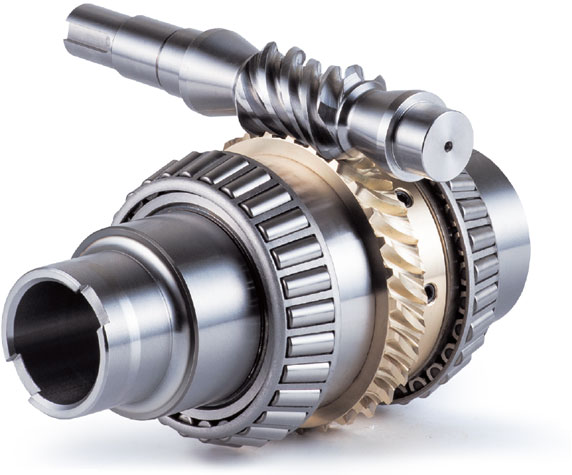

Globoidal Worm Gear

Introduction and advantages

Worm gears,

Worm gears include most general gears (spur gear, helical gear, planetary gear, bevel gear, harmonic gear, cycloid gear, etc.) Unlike these, the gear wheel tooth surface rotates and slides to transmit force, and the worm gear wheel shaft and the worm shaft intersects at 90 degrees.

Gear ratio of more than 10:1 can be produced, simplifying the design of multiple gear pairs and used in various applications, but have some defects in small teeth contact, heating, and low efficiency.

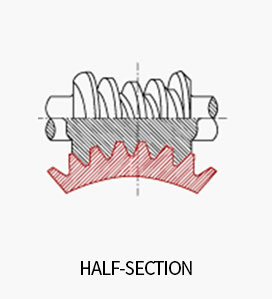

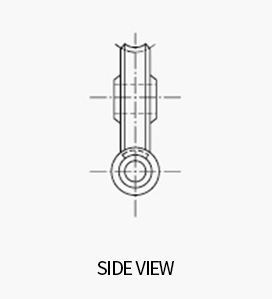

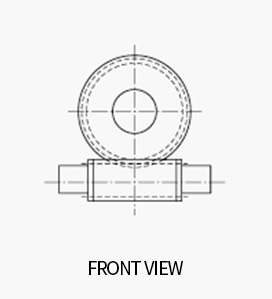

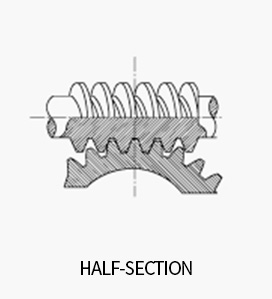

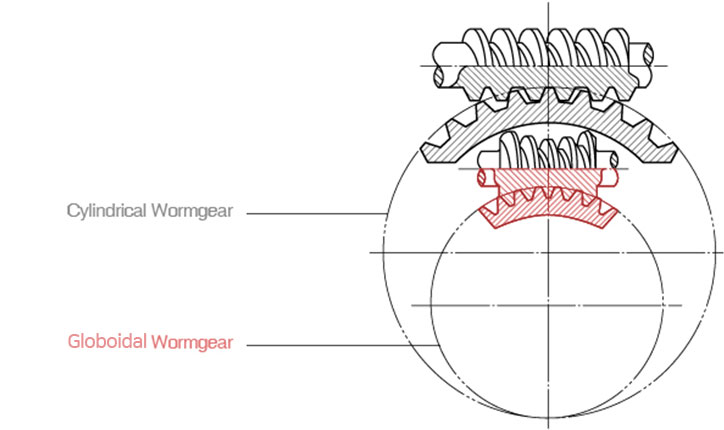

Hourglass worm gear SDG

The SDG's long-range flying gears, which can be traced to the ideas of Leonardo da Vinci in the 15th century, compare to ordinary (or cylindrical) flying gears showing dots or contact. As a structure in which the worm-safts and gears enclose each other, it embodies an extraordinarily wide "contact plane" and produces strong force and high efficiency. Also, force by optimized design Increase lubrication through dispersion to reduce heat and minimize noise and vibration to reduce energy consumption while ensuring long life.

A company that produces gears in the form of long-shaped wind instruments can be found,

but it can be found that there is a disadvantage of general-type air gear.

There are very limited companies around the world that produce truly long -

shaped gears that are all overcome. Germany In many countries that produce the best gears,

such as the United Kingdom and Japan, the type of gear that is more advanced is Zhang Gu type.

There was a development attempt, but all failed or switched to another gear.

SDG's long-range wind gear is 300% off-site impact compared to normal gear as well

as the performance of the gear itself In the areas that are unusually strong and require high safety

and stability, and in the areas where efficiency and life span are essential, there is no need for

development and environment There are many demands as a solution.

Leonardo da Vinci’s and his long worm gear sketches

Applications

Comparative data

1) Comparison of gear sizes with the same efficiency

2) Comparison of contact surfaces (long worm gears/general worm gears)

long worm gears

general worm gears

Globoidal Worm Gear

High load capacity and high efficiency power transmission

long worm gears have many teeth in the structure, the contact surface is relatively wider than general worm gears, so they can transmit higher loads effectively and transmission efficiency is up to 10% higher than general worm gears. A gear ratio of 30:1 can deliver about twice as much power to a gearbox of the same size.

Miniaturization, weight lightening, impact resistance

The number of teeth bite at the same time can transmit the same power in a smaller size than the general cylindrical gear, making it possible to miniaturize and light weight, high design scalability. In addition, it has high durability in shock resistance when starting and stopping. The impact resistance is 3 times stronger than general gears.

High Precision, high performance

backlash can be implemented and precise, making it suitable for varies application in industrial fields. Noise can be reduced by 5-10dB. Allowing for quiet operation and a relatively long life span.

Energy saving

relatively small volume and weight, and high transmission efficiency, it is eco-friendly due to high energy saving effect in long time operation.

| Gear Ratio | Long type worm gear efficiency | general worm gear efficiency |

|---|---|---|

| 30 : 1 | 80% | 75% |

| 40 : 1 | 76% | 70% |

| 50 : 1 | 73% | 66% |

(Base distance 2.0 inch, input rotation 1,750rpm)

| Gear Ratio | Long type worm gear efficiency | general worm gear efficiency |

|---|---|---|

| 30 : 1 | 1.40hp(1,210 in.Lb.) | 0.78hp(630 in.Lb.) |

| 40 : 1 | 1.05hp(1,155 in.Lb.) | 0.61hp(617 in.Lb.) |

| 50 : 1 | 0.84hp(1,110 in.Lb.) | 0.50hp(591 in.Lb.) |

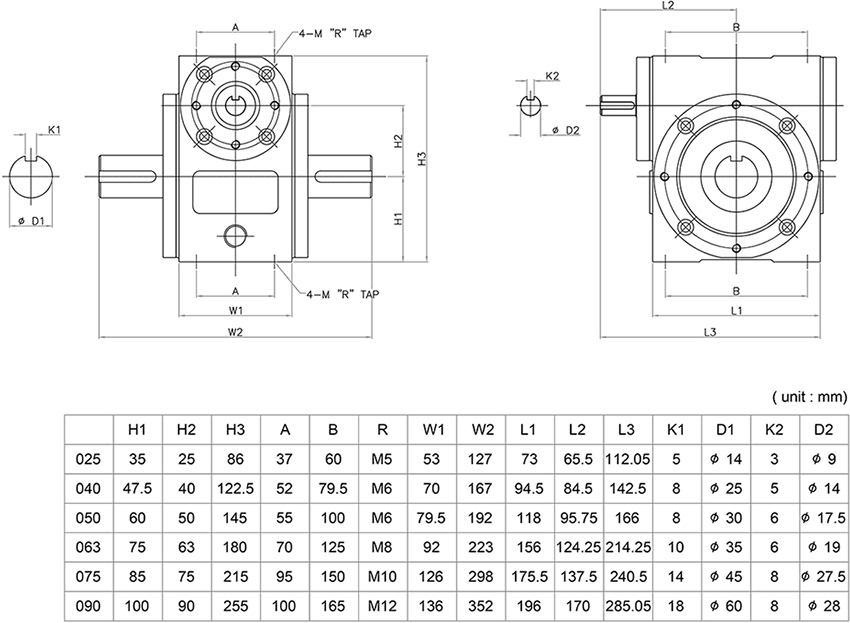

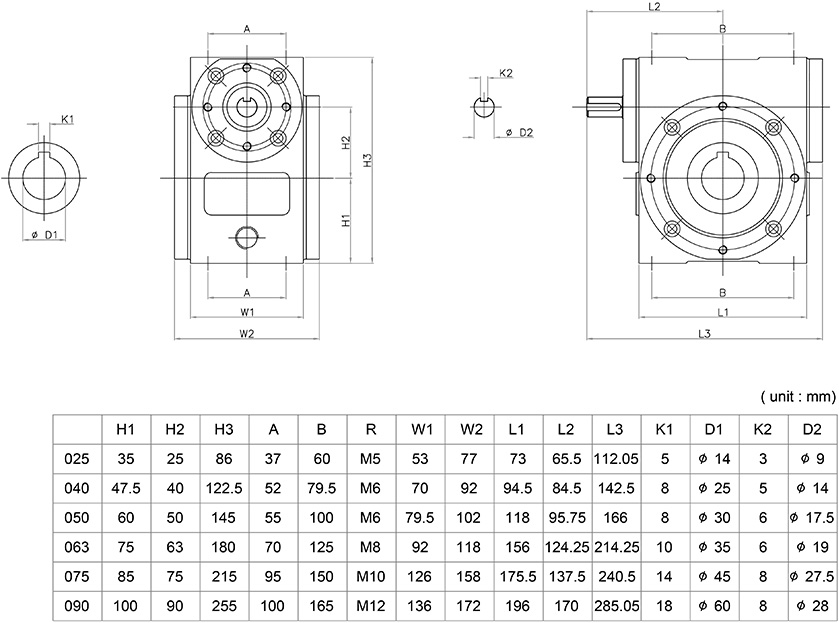

Hollow Shaft

Solid Shaft